Low-carbon and

circular precast

without changing your habits

Type 42.5, MCC1® cement for precasting is suitable for all production methods, including pressed or cast, reinforced, and non-reinforced concrete. It already complies with the regulatory requirements of the construction sector, including the 2031 threshold of the RE2020.

MCC1® 350

Practically, you don't need to change anything in your production units or in your manufacturing processes and timelines: MCC1® cement is fully substitutable for a conventional carbon-based cement.

In addition to meeting environmental requirements, you gain differentiation in your markets, and most importantly, you remain at a highly competitive cost!

MCC1® cement is particularly recommended for:

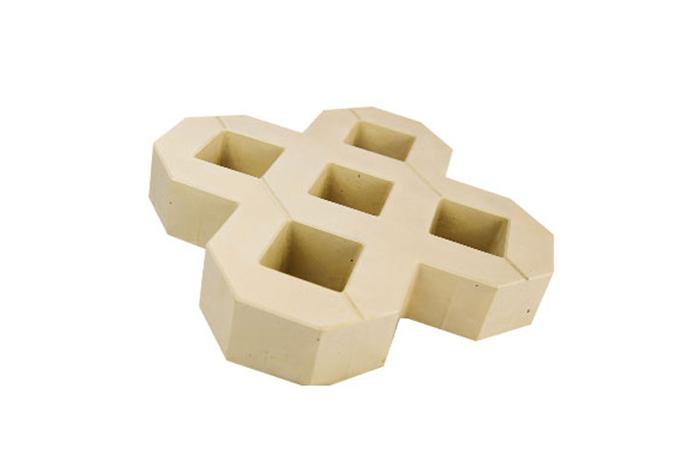

- Roads and public works: components for parking lots, retaining walls, bases, safety barriers, curbs, sidewalks, driveways, etc.

- Outdoor landscaping: elements for public spaces, pedestrian pathways, urban furniture, LEGO blocks for security or events, acoustic screens, etc.

- Construction: foundations, floorings, pre-walls and pre-slabs, construction blocks (B40-B60-rectified), pillars, beams, etc.

Type de ciment

Durée de vie

C25/30 - C30/37 - C35/45

Pour des bétons

XC4 / XF1 / XF3 / XS2 / XD3f / XA2

Classes d'exposition

Fondations - dallages - voiles

Applications

Ouvrabilité

Temps de prise au jeune âge

Change your carbon footprint, not your habits!

Our MCC1® cement is 100% compatible and substitutable for your precast elements.

Same tools

No investment required: Materrup solutions don't need specific tools. You use what you already have—same molds, same presses, same equipment

Same implementation

Materrup products are implemented in the same way as conventional materials on construction sites. No need to train your teams, no need to invest in specific equipment.

Compatible with conventional products

Materrup solutions are compatible with conventional materials (admixtures, mortars, coatings, etc.). You can simply change the cement!

Cost-effective

Because you need to maintain balance in your productions : our cement aligns with conventional pricing

And also: No overdosing. No over-reinforcing

MCC1® cement is used as a substitute for conventional carbon-intensive cement, enabling you to produce concrete elements that are more aesthetically pleasing, more durable, and equally high-performing

Same pace, same deadlines

MCC1® cement offers the same workability and early-age setting time as conventional carbon-intensive cement. The production rates in your plants remain unchanged: handling, curing, palletization... no need to change anything! The same expertise and duration for each step.

Our products in cast prefabrication

Materrup, in collaboration with its industrial partners, produces cast prefabricated elements using non-calcined clay cement.

Same manufacturing. Same factories. Same teams. Less carbon weight. Plus, enhanced aesthetics.

Our products in pressed prefabrication

Our industrial partners specialized in pressed concrete products replace conventional carbon-intensive cement with MCC1® cement. That's it. Same presses. Same curing. Same teams. Less carbon weight. Plus, enhanced aesthetics