Carbon impact : what are we talking about?

The real numbers that matter for your construction sites!

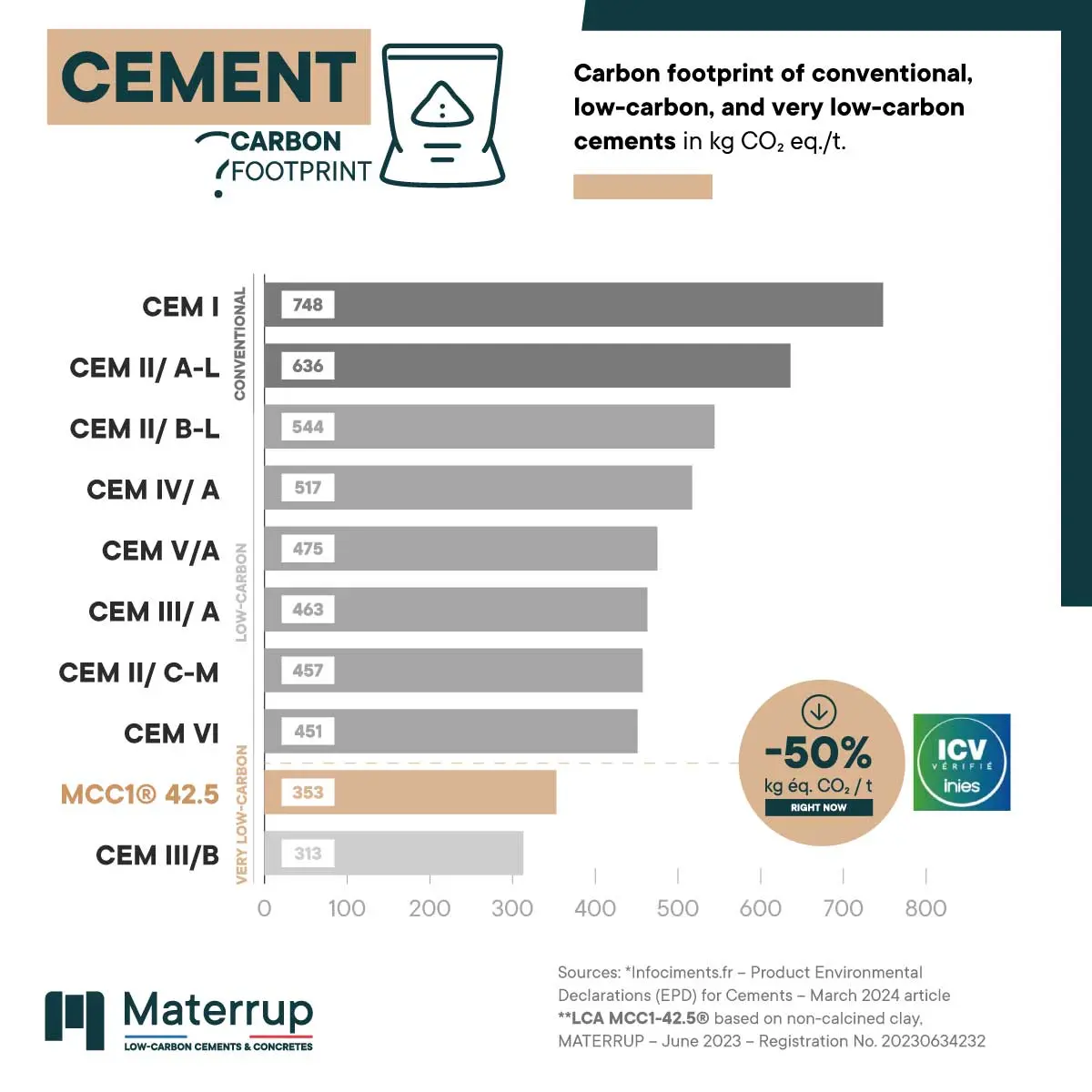

Immediately reduce the carbon footprint of your concrete by more than 50% without changing your habits thanks to our cold-activated clay technology MCC1® : By replacing your traditional cement and concrete with Materrup solutions, you instantly achieve a 50% carbon reduction!

And that’s not all: it also means less resource consumption, less energy, and less water.

Explanations so you can fully understand and act with complete transparency !

Because what you truly need on your construction site is a reliable and verified carbon footprint.

Because words alone are not enough, we have had our carbon footprint verified by independent accredited firms, for both cement and concrete.

Our Environmental and Health Product Declarations (FDES) have been produced and verified by independent, accredited verifiers.

Our FDES comply with the new standard NF EN 15804+A2..

Discover everything about our positive impacts!

No overdosing

No excess reinforcement

No extra cost

No purchase of new tools or machinery

Same workability

Same early-age setting

Same admixture possibilities

Same implementation as conventional concrete

Low carbon and beyond ...

Materrup is committed to protecting the climate and biodiversity. Reducing the carbon footprint is not enough. We must rethink our entire production model.

That’s why we have developed not only a disruptive technology, but also a circular one that transforms clay waste into a high-value, environmentally friendly construction material.

Unlike thermal industry processes, uncalcined clay – cold-activated is the main component of our MCC1® cement. This clay resource is abundant, recovered as waste from different sources. Raw, unprocessed clay from waste is intrinsically and undeniably low carbon — and it will remain so in the future.

But that’s not all! Our manufacturing processes are low-energy and non-thermal. Our plants have no kilns, no calcination, no flash furnaces. They run entirely on electricity, including solar panels installed on the roofs of the production units. The embedded energy is cut in half, helping to preserve natural resources, reduce reliance on fossil fuels, and offer competitive and stable prices, independent of fossil energy fluctuations.

-50% CARBON AVOIDANCE

Replacing conventional cement with Materrup low-carbon cement is the key to significantly and immediately reducing the carbon footprint of your project..

-50% ENERGY SAVINGS

Materrup’s low-energy process does not depend on fossil fuels. Our technology is based on cold activation and non-thermal processes..

RESOURCE PRESERVATION

Materrup uses recovered clay from waste streams. This by-product is abundant and local. These waste materials are transformed into construction products with high environmental value.

LOW CARBON, ACCESSIBLE TO ALL

An innovative solution that combines performance, environmental responsibility, and competitiveness to deliver positive impact.

A strong commitment: economic AND environmental performance

Because competitiveness must go hand in hand with efficiency on your construction sites, our prices are attractive and competitive.

INDUSTRIAL SOVEREIGNTY

Materrup strengthens industrial sovereignty for the entire construction sector, helping rebuild and secure French and European supply chains.

TERRITORIAL ATTRACTIVENESS

Materrup develops small-scale local production units, adapted to regions across France and Europe. This local network accelerates innovation, stimulates employment, and boosts territorial attractiveness

What does it actually change in practice ?

The lowest-carbon concrete block on the market

With equivalent performance :

MATERRUP B60 structural blocks = 9.41 kg CO₂ eq.

MATERRUP B40 precision blocks = 6.44 kg CO₂ eq.

B40 precision structural blocks with thin joints, assembled with conventional mortar, deliver an immediate and unprecedented carbon reduction of -37.5% compared to conventional blocks, and -43% for B60 blocks.

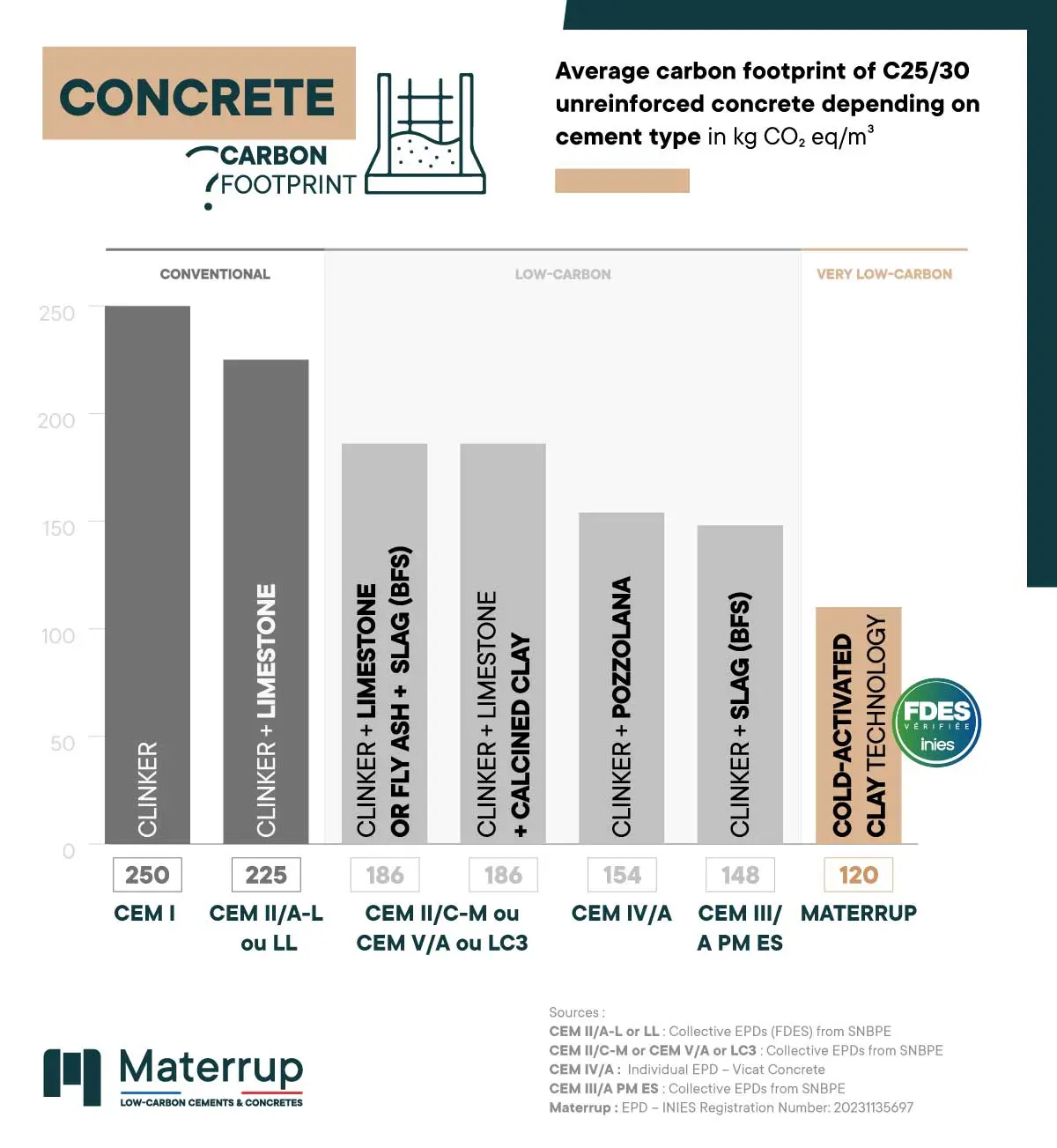

A low-carbon structural wall

Thanks to our disruptive low-carbon and circular cement technology, the C25/30 structural wall in Materrup uncalcined clay concrete delivers an immediate and striking 50% carbon reduction, with only 120 kg CO₂ eq./m³ compared to 246 kg CO₂ eq./m³ for a conventional CEM I wall.

Low-carbon standard and thermal precast walls

Materrup has partnered with FEHR GROUP to provide you with low-carbon and circular precast wall solutions.

-45% carbon footprint with the Précoffré® standard Materrup X FEHR, at just 22.2 kg CO₂ eq./m² compared to 40.2 kg CO₂ eq./m² with conventional CEM I cement..

-43% reduction with the Précoffré® thermal version with traditional insulation, at just 40.4 kg CO₂ eq./m² compared to 71.2 kg CO₂ eq./m² with conventional CEM I cement.I

Tangible impact in real numbers

Our innovative solutions are validated by construction experts.

Learn more about MCC1® technology