| High-performance hydraulic road binder

No compromises for your roadways: mechanical, environmental, and economic performance. Materrup has specifically designed road solutions incorporating CCC© technology and MCC1© cement for road construction or renovation, in-situ or central soil treatment, the production of base and subbase materials for pavements, and more generally for road sub-layers, as well as cold in-place recycling of old pavements.

Téléchargez la fiche technique depuis notre espace documentation (espace réservé)

No compromises for your roadways: mechanical, environmental, and economic performance.

Carbon reduction

compared to an equivalent conventional binder.

Materrup has specifically designed road solutions incorporating CCC© technology and MCC1© cement for base and subbase layers.

Our solutions are also suited for road construction or renovation, in-situ or central soil treatment, and cold in-place recycling of old and worn pavements.

INCLUDES MCC1® CEMENT TECHNOLOGY :

INCLUDES MCC1® CEMENT TECHNOLOGY :

Low carbon - Circular - Local - Economical - Easy to implement

Technical Performance

Designed to last, Materrup's hydraulic binder offers high mechanical properties, making it ideal for supporting heavy and repeated loads, even in the most extreme conditions. It remains unaffected by thermal deformations, erosion, abrasion, climatic aggressions, and chemical attacks, including those from fuels, oils, solvents, and other fluids.

HIGH ACTIVATION CAPACITY - Rapid reopening to traffic

HIGH ACTIVATION CAPACITY - Rapid reopening to traffic

Environmental Performance

- 47% reduction in carbon footprint compared to an equivalent conventional binder

- Use of recycled materials and site-sourced materials

- Preservation of natural resources, particularly non-renewable aggregate resources

- Cold process that protects teams during implementation and limits the use of non-renewable energy

- Reduction in transportation flows

- Minimization of nuisances generated during construction

- Protection of adjacent road networks

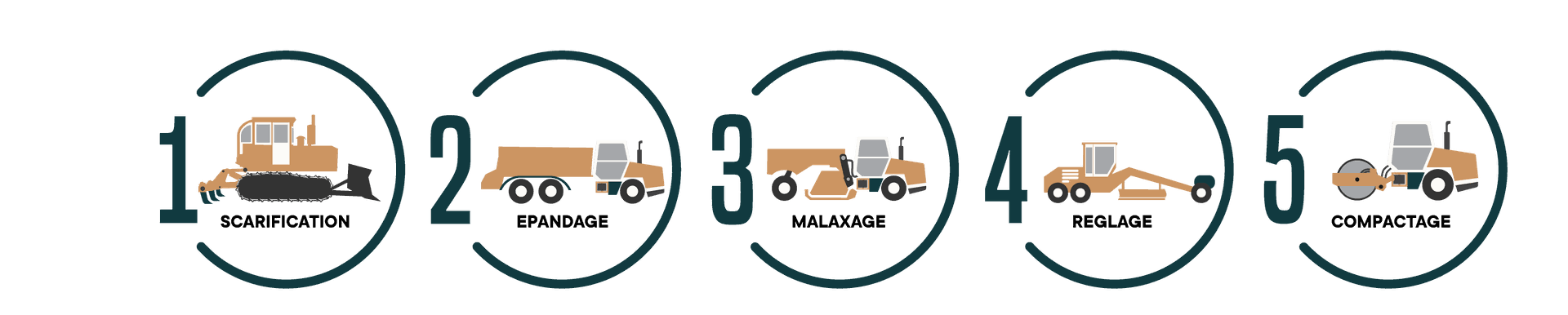

Simple and quick implementation

- Fixed or mobile Ready-Mix Concrete production units

- Rapid implementation, leading to minimal disruption in workspaces and on construction sites

- Very quick achievement of mechanical performance

- Rapid reopening to traffic

- Suitable even for late-season use

Economic solution

- Reduced energy consumption thanks to cold implementation

- Savings on transportation costs for materials and excavated soil

- Savings on landfill costs for excavated material

- Reduction in layer thickness and the number of layers

- Low maintenance costs

| Color | Grège |

| Made for : | Roadworks |

| Advantages | Structural |

| Areas of use: | Base and subbase layers, roadways, bicycle paths, embankment treatment |

| Resistance class | E4 |

| Performance on CEN mortar | at least equivalent to a road binder compliant with NF 13282-1 |

| Certification | ETPM issued by CSTB |

| Aligned with the standard | NF 13282-1 |

| Advice | A preliminary study is required to validate the application conditions and dosage of the binder. |

| Technology | Uncalcined clay cement MCC1© - CCC© Technology |

- Treatment of soils for base layers

- Treatment of soils for subbase layers

- Treatment of embankments

- In-situ soil treatment

- Cold in-place recycling of old pavements