NEW MCC2 ® Cement

The new generation of 42.5 cement: high-performance, accessible, and 74% less carbon-intensive.

A cement designed to accelerate, to decarbonize, and to transform the industry starting today.

The cold-activation revolution continues

Materrup introduces MCC2®, a 42.5 cement born from a strong conviction:

a 42.5 cement born from a strong conviction :

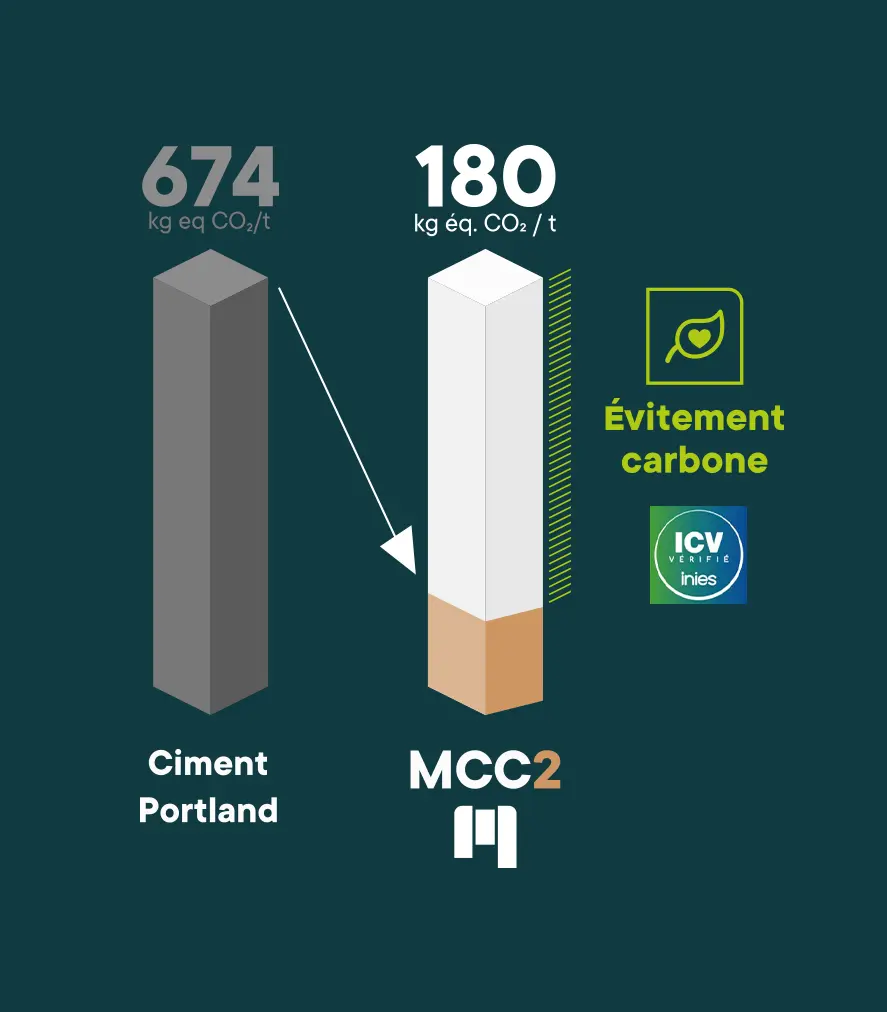

After a major breakthrough with MCC1 (350 kg CO₂/t), MCC2® pushes the limits even further:

• 180 kg eq. CO₂/t,

• –74% emissions compared to a conventional cement (~694 kg CO₂/t),

• C25/30 concretes under 100 kg CO₂/m³, reliable and ultra-low-carbon.

C25/30 concretes under 100 kg CO₂/m³, reliable and ultra-low-carbon.

Une technologie unique qui change tout : CCC®

Notre technologie propriétaire CCC® (Cold-activated Clay Cement) repose sur une idée simple mais radicale :

Il n’est pas nécessaire de calciner l’argile pour produire un ciment performant.

Avec MCC2®, nous prouvons que l’activation mécano-chimique permet :

use circular clay sourced from co-products and waste,

drastically reduce energy consumption,

cut carbon footprint by a factor of 4,

divide CAPEX & OPEX by 4 compared to calcined-clay technologies,

while ensuring robust and stable industrial performance.

Compliant with today’s standards, ready for tomorrow’s

MCC2® already meets regulatory and environmental requirements :

RE2020 — 2031 thresholds

CSRD (carbon, water, waste indicators)

Construction sector decarbonization pathways

Simple integration into existing processes, with no change in practices

For our partners only

MCC2® is designed for builders, industrial players, and specifiers who aim to:

reduce the carbon footprint of their structures,

secure their projects for 2025–2031,

remain competitive in tenders,

adopt a stable, protected, proven technology,

accelerate their transition toward low-carbon materials.

Same tools

No investment required: Materrup solutions do not require any special equipment.

You use what you already have — the same molds, the same presses, the same machinery.

Same implementation

Materrup products are implemented in exactly the same way as conventional materials, both on construction sites and in factories.

No need to train your teams, no need to invest in dedicated equipment.

Cost-effective

Because you need to maintain balance in your productions : our cement aligns with conventional pricing

And also: No overdosing. No over-reinforcing

MCC1® cement is used as a substitute for conventional carbon-intensive cement, enabling you to produce concrete elements that are more aesthetically pleasing, more durable, and equally high-performing